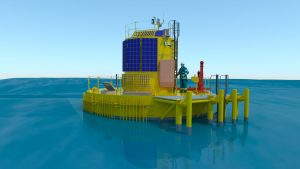

The NEMMO project has installed a set of tidal turbine blade panels made from fibreglass and a gel-coat coating for testing at the HarshLab facility. The samples, taken from the current Magallanes’ turbine blade, will be submerged for six months to determine the level of biofouling on the surface. These results will then be used as a reference for the development of new blade materials and coatings.

The creation of novel coatings and materials is a core part of the NEMMO project. After extensive modelling and testing, the team will define the optimal material composition, textures and surfaces to reduce wear on the blade. The wider objective is to lower maintenance costs and increase the yield of tidal turbines, and to improve the cost-effectiveness of tidal energy overall.

Check out the short video of the panels being installed at HarshLab’s floating offshore laboratory.

The Next Evolution in Materials and Models for Ocean Energy (NEMMO) project will boost the competitiveness of tidal energy by optimising tidal turbine blade design and performance.The project aims to create a larger, lighter and more durable composite blade for floating tidal turbines, enabling devices to reach capacities of over 2 MW.

The project’s work on blade materials comes under Work Package 3: Nano-reinforced composites, antifouling coatings and antifouling biomimetic surfaces.

NEMMO project has received funding from the European Union’s Horizon 2020 research and Innovation programme under grant agreement 815278