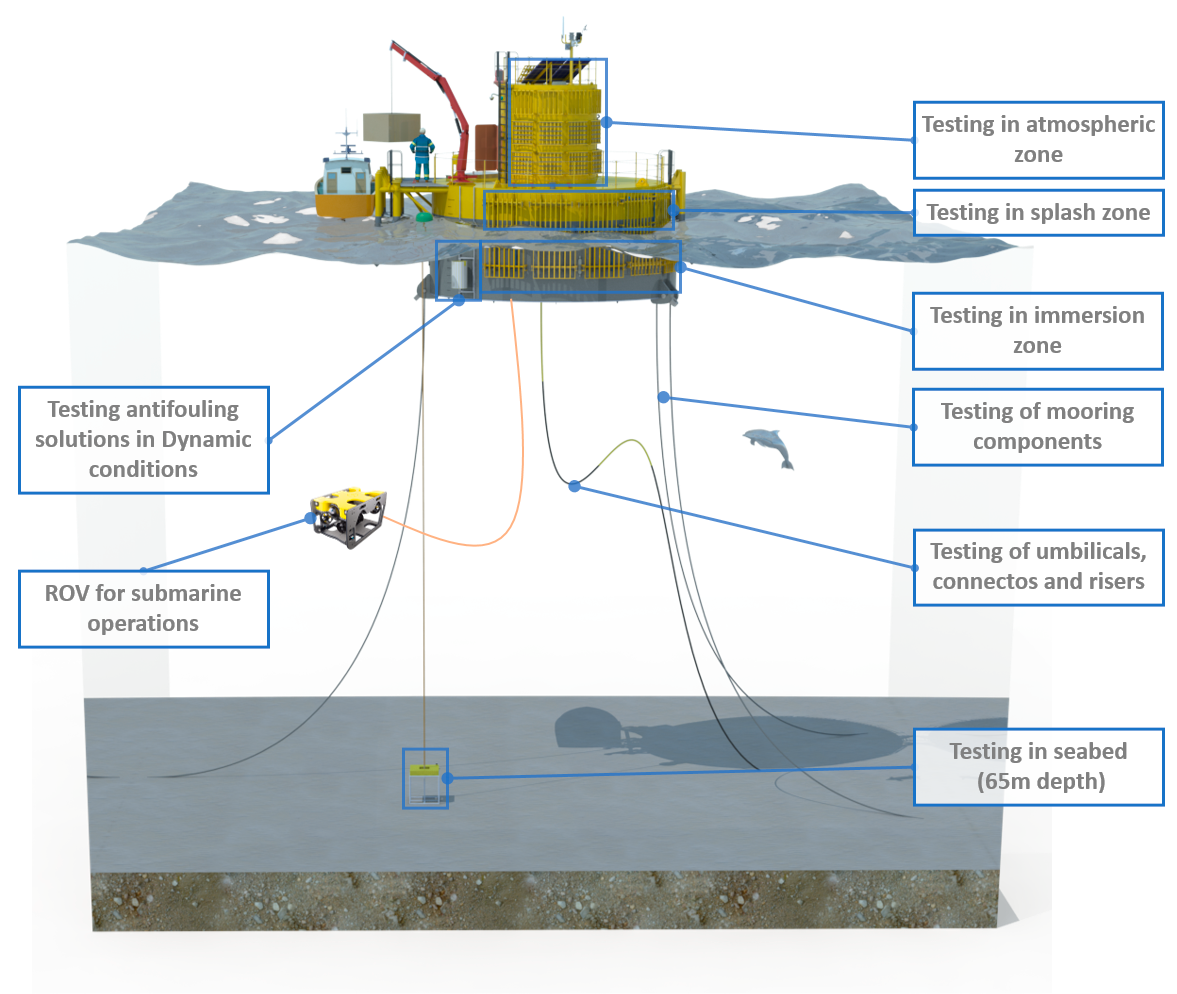

The new version of this unique infrastructure will enhance its potential to offer singular solutions to research projects related to offshore industries. New materials, components and equipment under operation in a variety of exposition zones (atmospheric, splash, immersion, confined and seabed).

HarshLab material and components lab is about to complete its third year in open sea conditions at BiMEP area (Biscay Marine Energy Platform). During this period, more than 20 companies have already tested more than 500 samples and obtained valuable information about their behavior in real offshore conditions. Anticorrosion, antifouling and antiaging solutions have been intensively tested in HarshLab through both private and public funded projects, including three Europe’s Horizon 2020 research projects.

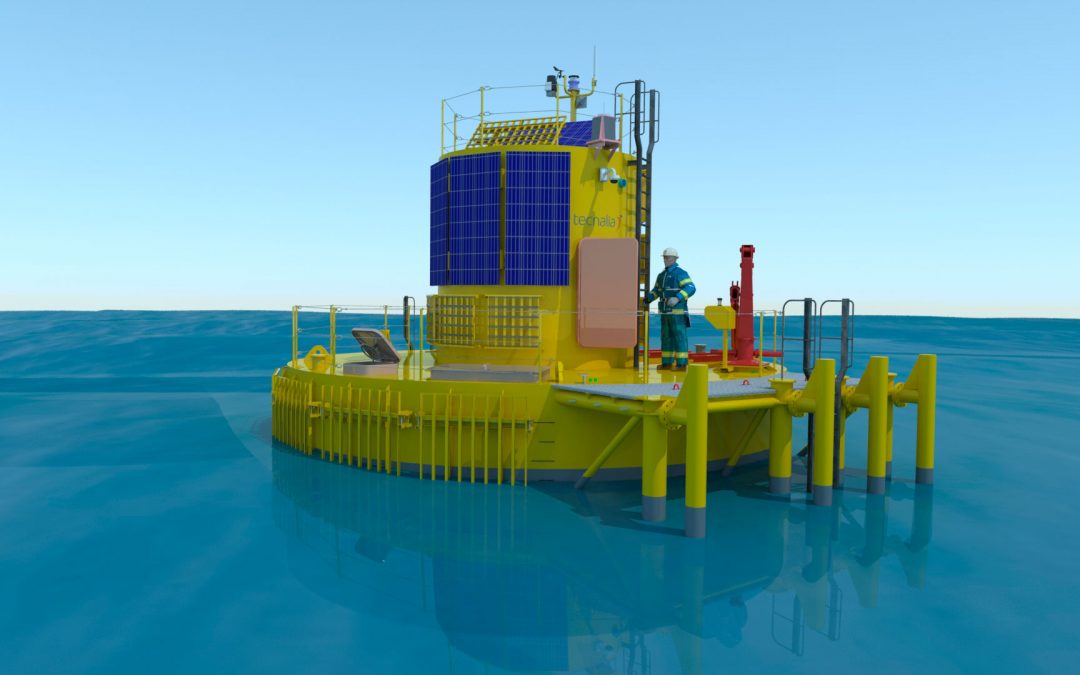

After three full winters withstanding the heaviest swells that swept the Bay of Biscay (including Epsilon hurricane in 2020), it is time to upgrade current version of HarshLab. This new HarshLab will add some additional testing capabilities to the lab that will increase its research potential to contribute to the competitiveness of the offshore industry.

The structure of the new version of HarshLab is currently under construction in a turnkey contract with IDOM, one of the leading-edge engineering companies in the Basque Country. Next four months will be crucial for the commissioning of the infrastructure 1,6 miles away of the Basque port of Armintza, and September is expected to be the starting signal for opening this new opportunity to offshore industry.

About the new HarshLab

This new HarshLab will be grid connected to the coast by an umbilical cable connected to BiMEP submarine cable net, which will provide the lab with both electric power and communications. This grid connection will open the possibility to test equipment under operation and will dramatically improve the capacity of handling heavy components onboard thanks to the installation of several cranes.

If we pay attention to the dimensions, thanks to its 8,5m diameter, 7m high hull and three decks, HarshLab will dramatically increase its capacity for testing materials in the same exposition sites already offered in the former version (atmospheric, splash and immersion), while adding two additional sites: testing inside the hold and at the seabed (65m depth).

But novelties don’t end here, as HarshLab will be equipped with some unique additional tools that will improve even more its added value: such two free connection hubs in the bottom of the hull for testing new solutions for risers, umbilical cables and submarine connectors; a submarine modem for testing communications from submerged equipment with the surface; a meteorological station; and a mini ROV for submarine inspections.