Testing

Conditions for the assesment

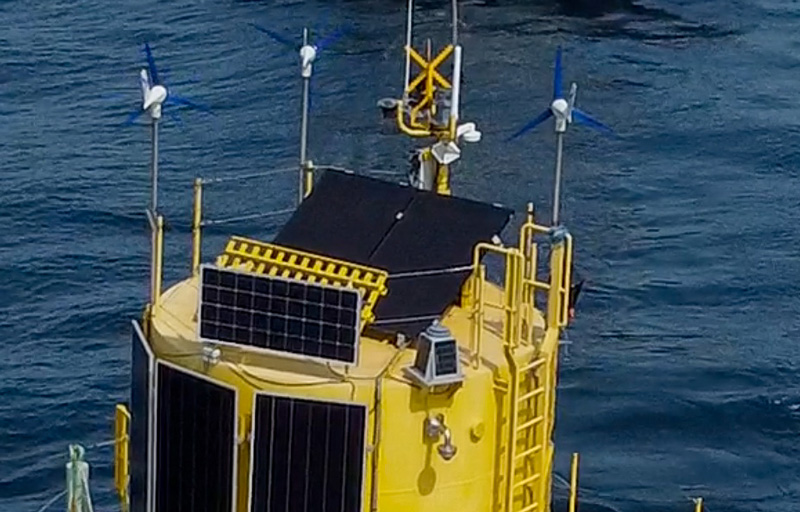

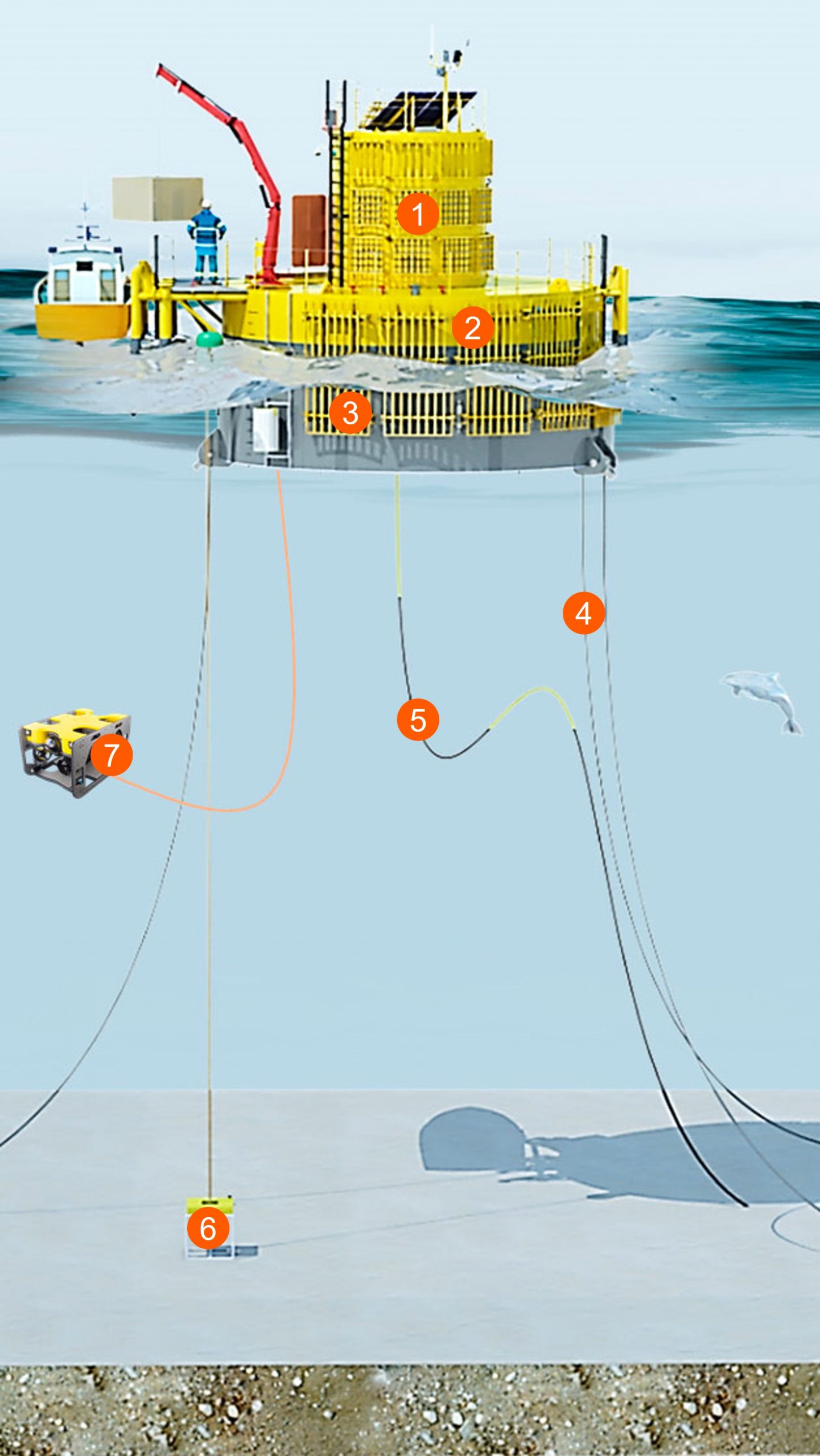

1 - Atmospheric Zone

Samples in atmospheric zone are between 1,5m and 5m above the sea surface, so depending on the meteoceanic conditions they will receive seawater sprays or not. Orientation and inclination of samples are different for each rack what will determine the corrosion rate for each sample position.

2 - Splash Zone

above the sea surface. Since HarshLab is a floating laboratory in open sea, it is not affected by tides and samples are continuously being splashed by salty waves, being the zone with higher corrosiveness. Here there are also differences depending of the orientation of the racks: W-NW face receives a more direct impact of waves.

3 - Immersion Zone

Samples in immersion zone are placed at a maximum depth of 2m below the surface, being heavily affected by fouling. During the first testing months, microalgae and bacteria start colonizing samples. Later a variety of macroalgae, molluscs and larvae that create a new ecosystem that will pilot the resistance of materials exposed here. The season of the year in key being the spring and the summer the periods with higher fouling growth rate. Once again, fouling growth is determined by orientation, observing relevant differences between the immersion exposition racks around the HarshLab.

4 - Mooring elements

HarshLab is a perfect environment for testing new mooring elements at different depths up to 65m of the seabed. The challenging meteoceanic conditions of BiMEP and the high growth of fouling in the first meters of the water column guarantee realistic conditions for any element of the mooring lines.

5 - Umbilicals, connectors and risers

The umbilical cable connection linking any floating element to the seabed is one of the Achilles heels of ocean energy. HarshLab has three connector spaces at the bottom of the hull, one of which is occupied by the 690V trifasic cable that powers the laboratory, while the other two are free for customer testing under the demanding wave conditions recorded at Bimep. This is undoubtedly one of HarshLab’s strengths for ocean energy collectors.

6 - Testing of components on the seabed

Thanks to the different lifting systems that the HarshLab has, it is possible to deposit samples and / or components for testing on the seabed (65m) or even in half depth. Our ROV allows us to perform easily periodic inspections of the tests.

7 - ROV for submarine inspections

Our ROV allows us to perform submarine inspections of customer tests as well as of our mooring system. It is also possible to perform submarine communications tests at depths of up to 65m. The ROV has a gripper that allows us to perform simple submarine operations, such as the recovery of elements in the seabed. The complete system of HD cameras of the ROV together with the good visibility of the waters of BiMEP enhances the possibilities offered by the HarshLab for submarine testing.

Types of testing

Corrosion

Atmospheric and splash zones have a corrosivity classification of CX. Immersion zone is classified as Im2, so both ensure the highest corrosion rate.

Ageing

HarshLab is a suitable site for testing materials and components of any material that need to withstand offshore conditions and to maintain its properties as flexibility, colour, brightness; among others.

Risers, conectors and umbilicals

HarshLab offers two available connectors in the hull, which poses an excellent opportunity for the validation of innovative connection systems of risers, conectors and umbilicals in real conditions.

Testing equipment in service

Able to host validation of grid connected prototypes in service in immersion, deck or in hold.

Antifouling

BiMEP is an open sea area especially prone to biofouling growth, so test immersion and splash zones of HarshLab are particularly suitable for testing experimental antifouling solutions under real offshore conditions.

Testing of offshore communication systems

HarshLab is a suitable place for testing all kinds of sensory and communication systems for the offshore industry. The Laboratory has a 3G telecommunication connection, meteorological station, GPS based tracking system, submarine modem for communications of submerged devices with Surface and a small ROV for inspections.

Additional testing in Laboratory

Obtained results in HarshLab can be complemented with test performed in our corrosion and characterization laboratories.

Additional specific corrosion tests, coating characterisation, ageing in climatic chambers or under mechanical solicitation, among others, can be performed according to international standards or specific demands.

- Corrosion analysis, forecasting, assessment, control and monitoring, as well as the assessment for the selection of materials for a specific application.

- Material and coatings testing and characterization (i.e. chemical composition, microstructure, mechanical properties, etc.).

- Surface properties, i.e.: surface roughness, coating adherence, wettability, hardness, …

- Failure analysis in-service performance and residual life

- Wear and friction characterization.

- Artificial ageing in climatic chambers

Data Lab Services

During the testing processes a multitude of data are gathered. This set of data can be provided to the user (meteorological data, oceanographic data, corrosion rate, appearance…). This data set makes possible to to take decisions in the assessment of the behaviour of the materials, components, and equipment in a real offshore environment.

We can provide also valuable correlations between the observed variables, using advanced data analytics techniques.